The Project

Goals

The results of the project have potential to contribute, together with the efforts made at European level in this area of research, to a paradigm shift in manufacturing, making it more economically viable, more flexible, safer, and improving the wellbeing and work opportunities of human operators. In short, the intention of this project was to contribute to the definition of a significant part of the technology that will incorporate the factories of the future.

- Implementation of a technological modernisation strategy aligned with Industry 4.0; Valuing the human being in the factories of the future;

- Making production processes more flexible;

- Dissemination, standardisation, and wide adoption of collaborative systems;

- Research and experimental development of a mobile collaborative system;

- Research of new interactive and collaborative models and behaviours;

- Empowerment of human resources through the creation of specialised jobs and new training offers;

Robótica Colaborativa Inteligente para Otimização Ergonómica de Processos Industriais

Consortium

Robótica Colaborativa Inteligente para Otimização Ergonómica de Processos Industriais

Project Activities

Overview, requirements, and specifications

This phase began with a study of the state-of-the-art directed towards a detailed analysis of technology, directives, and safety standards. Subsequently, the industrial requirements, general architecture, use cases, and metrics for system validation were defined. Finally, a business model for exploiting this new business area was proposed.

Human-robot interaction and collaboration models for assembly lines

This phase targeted the design and development of theoretical models to manage the fundamental behaviours of the system, namely, recognition, manipulation, locomotion, and safety. Finally, a virtualisation of the system was performed using a high-fidelity simulator.

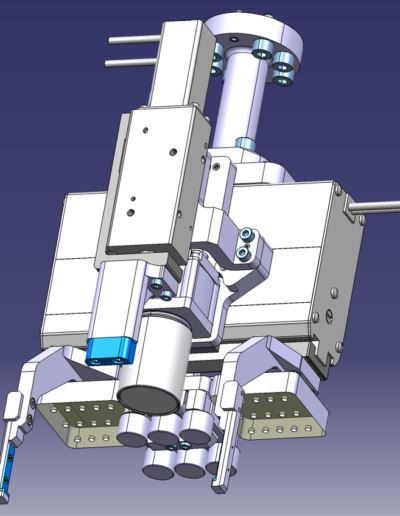

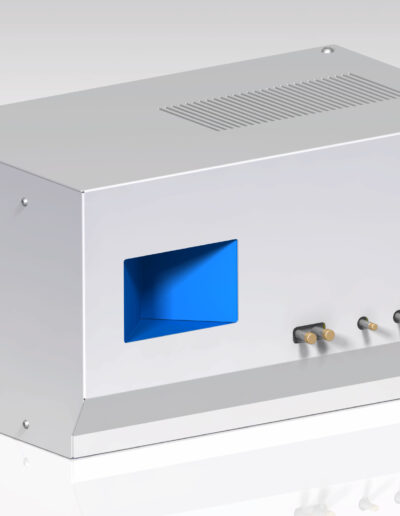

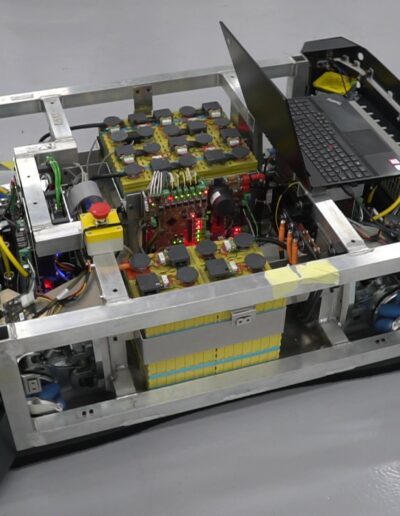

Robotic platform with collaborative capabilities

In the third activity, the physical platform of the collaborative system, including the mechanical structure and electronic components was conceived. The platform was divided into four main modules: interaction, manipulation, transportation, and safety. Finally, the integration of the developed modules and functional tests were carried out, respectively.

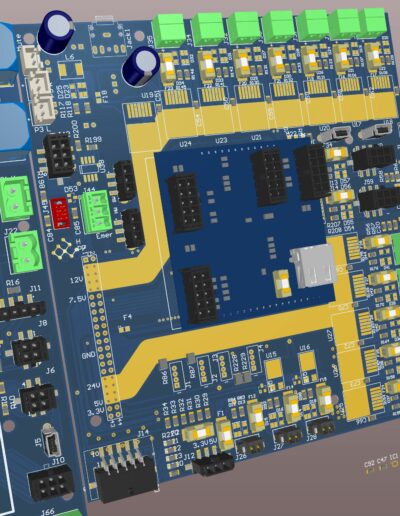

Implementation of the interaction and collaborative behaviour system

The fourth activity complemented the developments of the third activity. This aimed at creating the software platform of the Cyber-Physical system, including data acquisition and processing, control, and logical behaviour. As with the hardware platform (A3), the software platform was also divided into four main modules: interaction, manipulation, transport, and safety. Finally, integration of the developed modules and functional testing were performed, respectively.

Integration, testing, and final validation of the system

This phase of the project focused mainly on the integration and testing of the different modules developed in the previous phases. After their validation, they were tested, first in a controlled environment (TRL5), and later in a real environment (TRL7) at Volkswagen Autoeuropa premises.

Divulgation and dissemination

This last activity had as its main objective the assurance of the wide dissemination and scientific and industrial promotion of the system among potential stakeholders. To this end, several dissemination actions were carried out, including workshops, visits to industrial fairs, and the development of this website.

Results

The CONTIGO project ended in December 2022, highlighting the following proposed achievements:

- Development of a binpicking system for Volkswagen Autoeuropa parts and a customised gripper for this use case;

- Development of a platform for autonomous navigation, modelled and adaptable to different use cases;

- Development of intermediate software to make the developed system compatible with receiving orders from the manufacturing process management software (MES, Scada, or others);

- Integration and validation in a controlled environment at Introsys facilities;

- Integration and validation of the CONTIGO system in the factory environment, namely, in the logistics process of Volkswagen Autoeuropa;

- Elaboration of the project’s dissemination leaflet – objectives and 1st year results;

- Elaboration of the project’s dissemination leaflet – results achieved ;

- Creation of a video of project results

- Creation of the CONTIGO system product video

Events

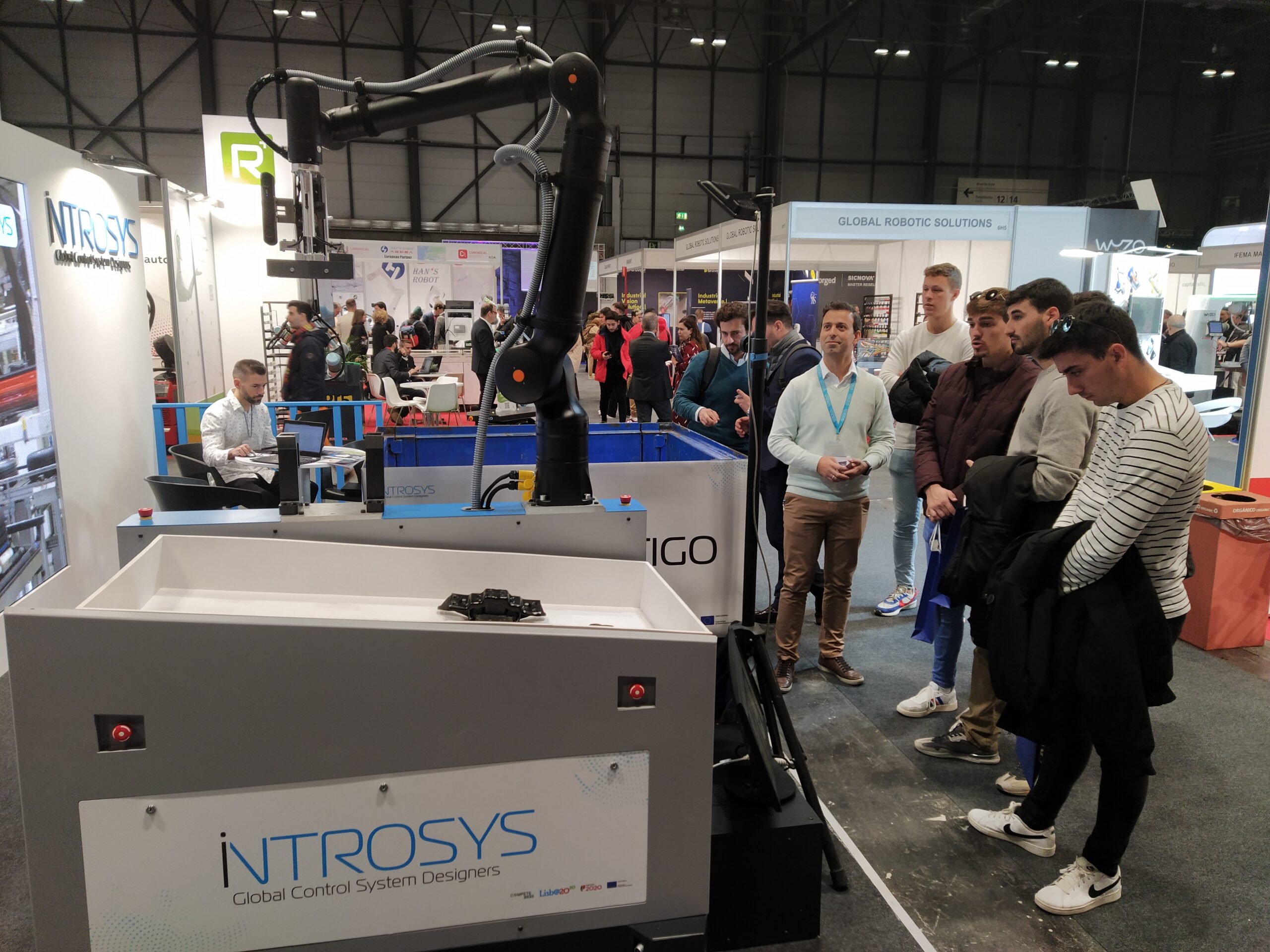

GR-EX | Global Robot Expo 2022

From November 30 to December 1, 2022, Introsys participated in the reference fair for industry 4.0, automation, artificial intelligence, and robotics, GR-EX | Global Robot Expo.

The CONTIGO project was presented in Madrid at the Introsys booth, and some details of the project were disclosed in the workshop with the theme Intelligent Collaborative Robotics for Ergonomic Optimization of Industrial Processes.

Project closure Workshop

As part of the dissemination activities of the CONTIGO project, on January 19, 2023, the closing workshop was held at Introsys’ facilities. This event had a technical and scientific nature in which the results achieved were presented and, finally, a demonstration of the different technologies was performed.

Contacts & LOCATION

Address

Estrada dos 4 Castelos Lote 67

2950-805 Quinta do Anjo, Portugal

Castelo Branco Delegation

CEI – Centro de Empresas Inovadoras, Salas S2.05 e S0.02

Av. do Empresário 1,

6000-767 Castelo Branco, Portugal

GPS: N 39°48’51.8 W 7°30’24.1

Contacts

+351 212 951 499

Chamada para rede fixa nacional

© 2021 INTROSYS – Projeto CONTIGO. Todos os direitos reservados.

Desenvolvido por Bestsites